Knothole Sawmill

Turning your logs into lumber at your location

Want to learn more about sawmill's, Sawyers and the sawmill trade?

Air Drying Lumber

For exterior or construction uses, best results can be obtained by air drying lumber. The degree of wetness in wood is called moisture content, and it's expressed as a percentage. Depending on your particular area air drying can bring the moisture content down below 7% making your material suitable for interior cabinet work

and furniture. This process is easy and free.

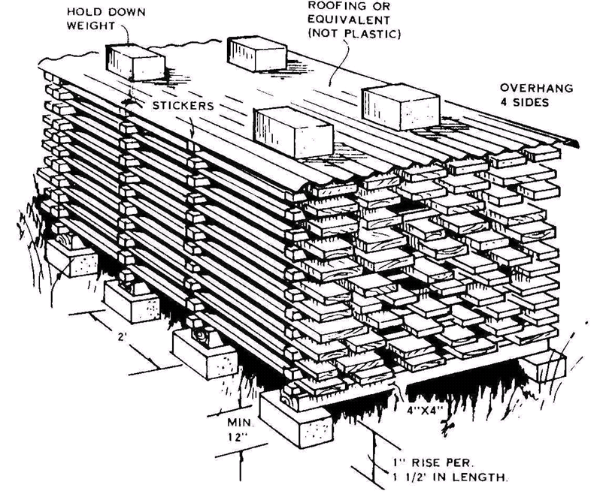

Green lumber should be stacked on stickers as soon as possible after sawing. This improves air circulation between the boards, speeds drying and prevents discoloration. Applying an end sealer to the boards will reduce splitting and saves as much as 10% of the lumber value.

Properly stacked lumber dries quickly in warm, dry weather. Softwoods like pine and cedar will air dry to suitable moisture content in as little as 6 weeks during the spring and summer months. Hardwoods like Maple, Oak and Walnut will dry in 6 -12 months. Little or no air drying takes place in wet damp weather.

The illustration below shows a properly stacked pile of green lumber. The "stickers" (1" X 1") and top weights should be aligned vertically and placed about 2 feet apart.

Cover the top of the pile with a tin sheet with overhang on all sides. Leave a space between the cover and the lumber pile.

For exterior or construction uses, best results can be obtained by air drying lumber. The degree of wetness in wood is called moisture content, and it's expressed as a percentage. Depending on your particular area air drying can bring the moisture content down below 7% making your material suitable for interior cabinet work

and furniture. This process is easy and free.

Green lumber should be stacked on stickers as soon as possible after sawing. This improves air circulation between the boards, speeds drying and prevents discoloration. Applying an end sealer to the boards will reduce splitting and saves as much as 10% of the lumber value.

Properly stacked lumber dries quickly in warm, dry weather. Softwoods like pine and cedar will air dry to suitable moisture content in as little as 6 weeks during the spring and summer months. Hardwoods like Maple, Oak and Walnut will dry in 6 -12 months. Little or no air drying takes place in wet damp weather.

The illustration below shows a properly stacked pile of green lumber. The "stickers" (1" X 1") and top weights should be aligned vertically and placed about 2 feet apart.

Cover the top of the pile with a tin sheet with overhang on all sides. Leave a space between the cover and the lumber pile.